Latest Research Reveals Silver Enhances Electric Car Battery Performance

- 08/05/2015

- Transport

- Posted by Tessa Romarez

- 2 Comments

Today’s research and development will one day give the world an electric car battery that is cheaper, smaller and will enable drivers of electric vehicles to travel greater distances with one charge.

Such a battery is now being developed by a team of researchers at the U.S. Department of Energy. This team hopes that when this battery is completed, it can store 10 times more energy than the lithium-ion batteries used by most electric cars today.

Larry Curtiss, a materials scientist and his team of researchers at the USDOE is working on new battery architecture. This new battery uses lithium-oxygen bonds as it captures and releases energy. The battery also uses silver as the metal catalyst that makes the first process possible.

With this new architecture, the team hopes to develop a battery that can store up to 10 times more energy than current Li-Ion batteries. It should also increase the mileage range of one charge from 400 to 500 miles.

This new battery energy storage system does not follow the usual charging and releasing of electrical energy that all Li-Ion batteries perform. In this new battery, oxygen and lithium atoms combine to create chemical bonds.

This releases more energy in the same amount of space, because the elements have higher energy density. However, a metal catalyst is needed so that chemical bonds between the elements can be formed.

During their experiments using different types of precious metals, the research team found that tailored clusters of silver atoms are able to provide the surface texture needed to develop the lithium-oxygen bonds in great amounts.

“In previous studies, we’ve had metal catalysts that helped the formation of these bonds, but we never knew what size these catalysts were—they could be from thousands to a couple of atoms in size,” Curtiss explained.

“Now we’re actually able to put down specific size clusters of silver and see what effect it has on the formation of these lithium-oxygen bonds,” he added.

Stefan Vajda, an Argonne materials scientist, said that using the ultra-small clusters as catalysts for electric battery electrode is unique. This method was suggested because several studies have revealed that the small clusters can easily energize, or break apart oxygen to enhance chemical reactions and release more energy.

“Once we understand how the process works and determine what size clusters perform the best, then we can design catalysts that work well, perhaps using lower-cost metals,” Vajda explained.

At present, Argonne is the leader in the understanding of the fundamentals of this type of battery energy storage chemistry. But the commercialization of this technology may take another 10 to 20 years.

Understanding the reaction of the metal catalysts is just the initial step. More research is needed to overcome several technical issues before the battery can be considered road worthy.

But it is believed that when all of the issues are resolved, this new lithium-oxygen architecture, together with its ultra-small silver and other metal clusters that efficiently direct energy productivity, could provide car manufacturers and car owners a high-efficiency, lower-priced alternative to current batteries for electric vehicles.

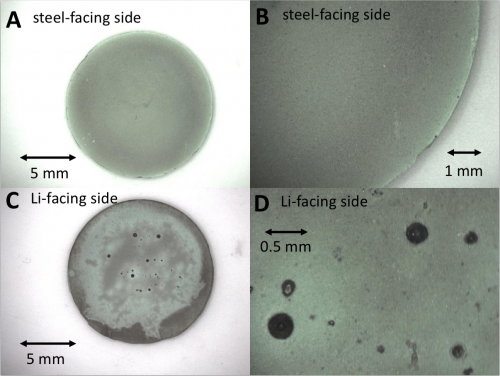

Photo Credit: Stony Brook University/Brookhaven National Laboratory